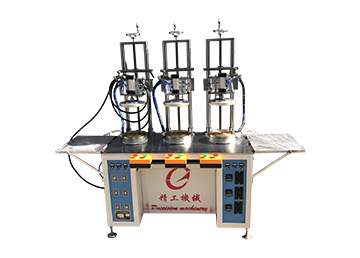

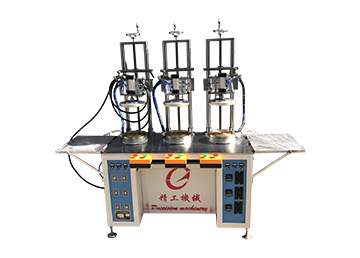

精工圓筒機(jī)廠(chǎng)家告訴你卷邊機(jī)的操作方法與技巧,。精工圓筒卷邊機(jī)分:雙工位圓筒卷邊機(jī),,三工位卷邊機(jī),,四工位自動(dòng)圓筒卷邊機(jī)及全自動(dòng)卷邊機(jī);

一,、 操作步驟:

一,、 操作步驟:

1) 接好空氣壓力,,把壓力調(diào)到合適(4-5KG/cm2);

2) 打開(kāi)電源開(kāi)關(guān),,電源指示燈亮,;

3) 打開(kāi)調(diào)模開(kāi)關(guān),卷邊氣缸會(huì)下降50mm,;

4) 把需要卷邊的圓筒放到模盤(pán)上面,;

5) 松開(kāi)導(dǎo)桿上鎖緊的旋轉(zhuǎn)手柄螺絲,,使用頂部手輪上模頭可以上下移動(dòng),將上模盤(pán)調(diào)整至圓筒上面1-2mm左右(即打開(kāi)調(diào)模開(kāi)關(guān)時(shí)不要碰到圓筒即可)隨后鎖緊調(diào)節(jié)螺絲,;

6) 關(guān)掉調(diào)模開(kāi)關(guān),,打開(kāi)預(yù)熱溫度和加熱溫度開(kāi)關(guān),,隨材料不同,,調(diào)

整至合適溫度,(PVC85ºC左右,、APET75ºC左右,,僅供參考);

7) 完成以上步驟后,,就調(diào)整好機(jī)器了,。在溫度合適時(shí)將圓筒放在模

具內(nèi),按下起動(dòng)按鈕就可卷邊,;建議轉(zhuǎn)動(dòng),,打開(kāi)調(diào)速器開(kāi)關(guān);

8) 卷邊的高度可以使用調(diào)節(jié)行程控制高度來(lái)控制,,卷邊速度可以由調(diào)壓閥和加熱溫度來(lái)控制,;

二、 維修保養(yǎng):

1) 本機(jī)器維修簡(jiǎn)單,,基本上不需要維修,,只需一個(gè)月內(nèi)檢查一

次存油缸的存油量,按油缸容量的70%為準(zhǔn),;

2) 當(dāng)發(fā)現(xiàn)卷邊速度有快有慢時(shí),,行程不穩(wěn)定,請(qǐng)將調(diào)壓閥開(kāi)到

最大值,,將卷邊行程松開(kāi),,然后空載運(yùn)行多次,直到缸內(nèi)空

氣排完為止(遇到此問(wèn)題時(shí),,請(qǐng)打電話(huà)到我司咨詢(xún)),;

3) 氣缸不動(dòng)作:檢查電磁閥線(xiàn)圈有無(wú)燒壞(如線(xiàn)圈燈不亮,則

表示燒壞,,需更換),。

4) 發(fā)熱盤(pán)不發(fā)熱:檢查溫控器是否正常;

5) 油壓閥失靈:不能控制快慢,。

A, operation steps:

1, connect the air pressure, the pressure to fit ( 4-5KG/cm2 );

2, turn on the power switch, a power indicator light;

3, open the mold adjusting switch, curling cylinder will decline 50mm;

In 4, the need for crimping cylinder into the mold disc;

5, undo the guide rod for locking the rotation of the handle screw top, use hand wheel die head can move up and down, the upper die plate to adjust to the cylinder above about 1-2mm (i.e. open the mold adjusting switch without touching the cylinder can) subsequently locking and adjusting screw;

6, turn off the die adjusting switch, open the preheating temperature and heating temperature switch, with different materials, adjustableThe whole to the appropriate temperature, ( PVC85 ºC, APET75 ºC, for reference only);

In 7, after completing the steps above, adjust good machine. The temperature is appropriate the cylinder inside the moldInside, press the start button can be curled edge; suggest to rotate, open the governor switch;8, crimping height can be used to control stroke adjusting control height, hemming speed can be determined by a pressure regulating valve and the heating temperature control;

Two, repair and maintenance:

In 1, the machine repair is simple, basically do not need repair, just a month to checkSaves the oil cylinder of the oil storing quantity, according to the cylinder capacity of 70%;

In 2, when the roll rate, stroke is not stable, the pressure regulating valve to pleaseThe maximum value, the crimping stroke loose, then running times, until the in-cylinder airGas discharge date ( encounter this problem, please call our consultation );

In 3, the cylinder does not action: check electromagnetic valve coil is burnt out ( such as coil lamp is not bright, thenExpress burn, need to change ).

In 4, the heating plate fever : an examination of the thermostat is normal;

5, hydraulic valve failure: unable to control speed.

卷邊機(jī)設(shè)備的基本參數(shù):

|

型號(hào) Model |

JG-2102,、JG-2103 |

|

適用材料 Material |

PVC、PET,、PP,、塑料及紙筒 |

|

功率Power |

5000W |

|

生產(chǎn)卷邊直徑 Dia. |

¢15-200mm(大直徑可定做) |

|

生產(chǎn)卷邊長(zhǎng)度 Length |

15-420mm |

|

電源電壓 |

220V |

|

生產(chǎn)速度 Speed |

3-6秒 |

|

外形尺寸(L×W×H)Demension size |

1100mm*550mm*1700mm |

圓筒卷邊機(jī)生產(chǎn)出產(chǎn)品效果圖:

圓筒卷邊機(jī)生產(chǎn)出產(chǎn)品效果圖: